The automotive and aerospace industry have seen incredible advances in recent years, thanks to the introduction of laser machines. These cutting-edge devices are revolutionizing manufacturing processes by making them faster, more efficient, and cost-effective.

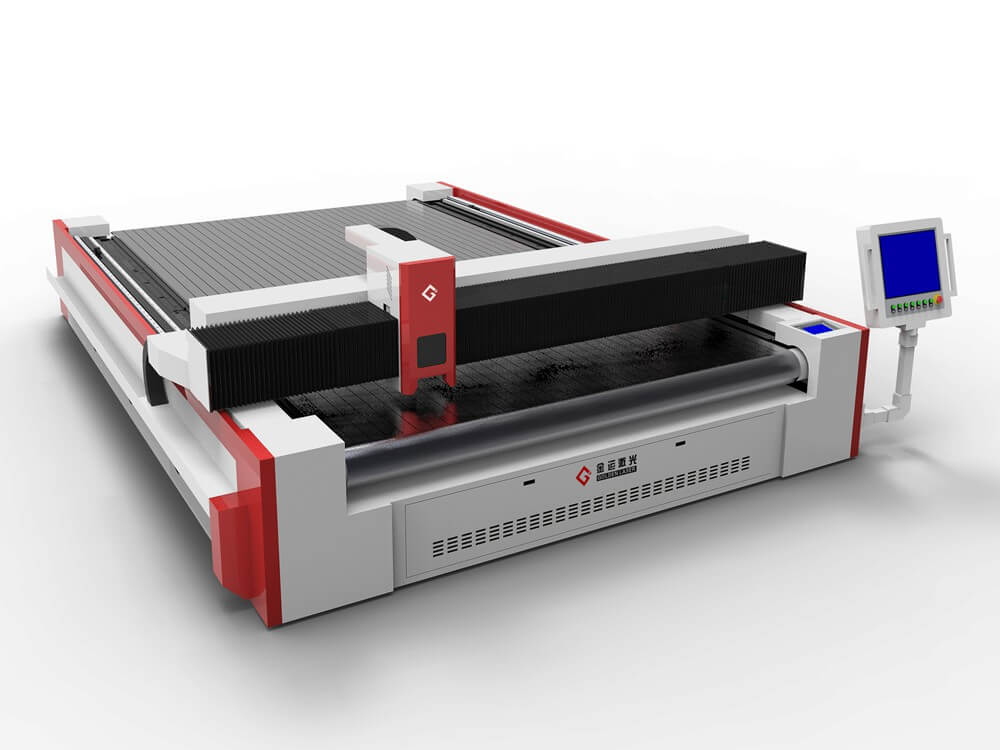

Laser machines can cut or shape materials into complex designs with unprecedented precision and accuracy. They can also be used for welding, marking, or engraving a variety of components.

As a result, they are playing an important role in advancing these industries forward. From improving safety measures to creating cutting-edge technology – laser machines are transforming the way we build cars and aircraft today!

Laser Machines Increase Automotive and Aerospace Efficiency

Laser machines have revolutionized the automotive and aerospace industries, offering immense opportunities for efficient manufacturing. These lasers offer unparalleled accuracy and precision when it comes to cutting metal components with minimal waste.

The use of laser machines in these sectors is now widespread, allowing manufacturers to cut complex shapes quickly and easily. This increase in efficiency has enabled many companies to reduce their production costs while still producing high-quality parts that are both reliable and strong.

In addition, laser machines allow for faster turnaround times on projects by reducing time spent manually machining parts or welding them together using traditional methods. With shorter lead times, businesses can produce larger quantities more quickly while maintaining a consistently high level of quality throughout their production process.

Furthermore, laser technology offers tremendous savings in energy usage as well as improved safety due to its lack of open flame or sparks which could cause fires or other hazards in an industrial setting. The use of laser machines also ensures greater consistency throughout the entire production process from the design stage through final assembly, creating products with fewer defects that require less manual rework resulting in cost savings over time as well as enhanced customer satisfaction with each product made using this advanced technology.

All these benefits make laser machine automation an invaluable asset for any company looking to maximize productivity within its operations while still ensuring high standards are maintained across its portfolio of services offered to customers worldwide.

Improved Precision with Automation from Laser Technology

The automotive and aerospace industries have experienced a revolutionary change with the advent of laser machines. Laser technology has enabled manufacturers to increase precision while streamlining production processes, leading to higher efficiency and accuracy in completing projects.

With the implementation of laser machines, intricate components can be produced faster and more accurately than ever before. This increased accuracy is because lasers are highly precise tools that allow for near-perfect alignment of parts with minimal human intervention.

Additionally, automated systems utilizing lasers can also improve safety by eliminating potential hazards associated with manual labor tasks such as welding or cutting metal pieces. The use of laser technology provides numerous benefits for these industries, from improved performance to reduced costs and time spent on projects.

Benefits of Using Lasers in the Auto and Aerospace Industries

The automotive and aerospace industries have seen a significant increase in the use of laser machines over the past few years. These machines offer numerous benefits, including greater precision and accuracy, improved efficiency, and quicker turn-around times when it comes to manufacturing parts for vehicles or aircraft.

When used in production processes, lasers can produce highly intricate designs with a high degree of detail that would be difficult or impossible to achieve using traditional methods. This allows for more complex components to be produced faster than ever before.

Laser cutting also eliminates the need for manual processes such as drilling and sawing – further reducing time spent on production lines while maximizing output quality. Lasers can also reduce costs associated with producing parts due to their increased accuracy and efficiency. By utilizing precise measurements during fabrication, wastage is minimized leading to cost savings across entire projects.

Conclusion

The automotive and aerospace industries have been revolutionized by laser machines. Laser machines can cut, weld, clean, drill, and mark with precision accuracy, and speed.

They are also able to handle a wide variety of materials including metal alloys, plastics, composites, and ceramics. With the increasing demand for improved performance in vehicles and aircraft comes an increased need for new technologies like laser machines that provide faster turnaround times and improved efficiency.

This has enabled these industries to reduce production time while still maintaining high-quality standards. Overall, laser machines are enhancing the automotive and aerospace industries by allowing them to produce more efficient products at faster speeds than ever before.

To learn more about how these powerful tools are impacting industry progress click here!